Industrial Electronics

Static charge is known to damage microelectronic components, industrial equipment, and computers. There is also an increased propensity for people to build up a static charge on themselves just by everyday movement and then transfer the charge to sensitive parts and devices causing damage.

Reasons to Eliminate Static

- Eliminate material jams

- Increase processing speeds

- Clean surfaces

- Prevent particle attraction

- Eliminate volatile solvent hazards

- Improve product yield

- Prevent static-induced damage to processing equipment

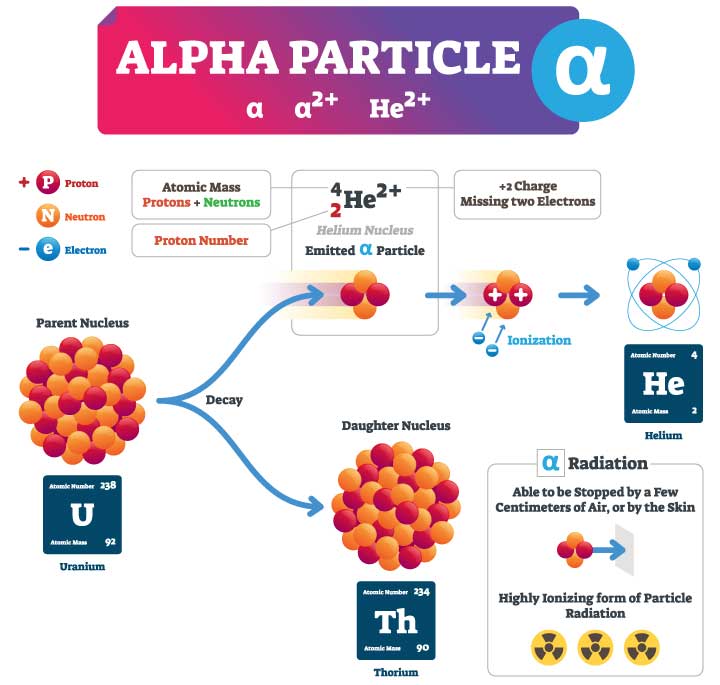

Alpha Energy

Incredibly fast decay rates that quickly neutralize static charges.

- Continuous, self-powered dense cloud of ion generation

- Reliable, constant and stable voltage balance of ± zero volts

- Zero ozone emitted

- No maintenance or calibration throughout the life of the ion source

- No production downtime or yield losses

- Clean ionization without emitter shedding

- No risk of electrical shock hazards enabling usage in volatile atmosphere.

- No operating costs associated with ion sources

- No radio frequencies produced to interfere with process controls

- Vibration and impact resistant

- Completely safe and portable

NRD Air Ionization Products

Controlling static is the key. The proper application of ionization can be an effective component of an overall strategy to control static electricity. Some of the benefits realized in the effective application of air ionization devices include:

Improved Product Quality and Increased Yields

- Improved removal of dust and particulate contamination from critical surfaces

- Minimized defects in finishing and coating applications

- Improved cleaning of parts and assemblies after molding and machining operations

- Reduced damage from spark discharges to plastic film surfaces prior to printing

- Improved uniformity of coatings applied to substrates such as DVD optical media

- Improved yield of sensitive electronic components

Increased Productivity and Process Speeds

- Reduced microprocessor, robotic and automated equipment lock-up

- Reduced jamming and restrictions on sheet-fed and web printing equipment

- Increase web speeds in extrusion, laminating and converting applications

- Reduced handling, inspection and cleaning of parts and assemblies

- Improved flow of raw materials, product and waste in injection molding, powder processing and small parts manufacturing

Safer Work

Environments

- Reduced shocks to personnel

- Reduced static damage to microprocessors and automated equipment

- Reduced spark hazards in volatile solvent environments

Explore Products

For more information about our products and solutions for your operation, please contact NRD, LLC today.

Tell Us More About the Problem You Need Solved

To make sure we offer the best solution possible, we’d like to know more about your project and how we can help. Fill out the form and, if available, upload any files that are pertinent to your specified parameters. An expert team member will reach out once all information has been gathered.

NRD, LLC USA Headquarters, Sales & Manufacturing

2937 Alternate Blvd

Grand Island, NY 14072

NRD Asia Pte. Ltd.

26 Kallang Place, #06-17

Singapore 339157

Phone:

+65 6679 1707

NRD, LLC USA Headquarters, Sales & Manufacturing

2937 Alternate Blvd

Grand Island, NY 14072

NRD Asia Pte. Ltd.

26 Kallang Place, #06-17

Singapore 339157

+65 6679 1707